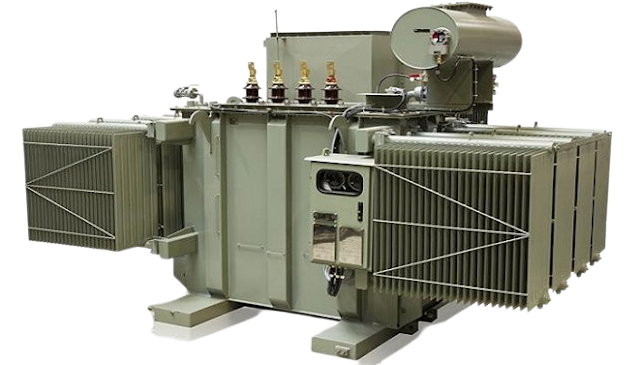

BIS ISI Marked Distribution Transformer as per IS:1180 Part 1(2014)

Every single transformer is designed according to the individual customer requirement such as Voltage, Power System Parameters, Location Geography, System Disturbance Level and many more including National / International standards with a vision of bringing reliable quality power safely to the end consumer.

Special features of Oil type BIS ISI Marked Distribution Transformers include:

Distribution Transformers are tailor made to each & every requirement of customers conforming to National & international Standards.

- Transformer is designed by experienced expert engineers using most modern software programs.

- The process blueprints for each transformer is prepared advanced technologies like AutoCAD & ProE to ensure adherence to the design parameters.

- Highly skilled Transformer Production wing with state-of-the-art manufacturing facilities.

- Transformer losses are minimized by the usage of high quality & high grade CRGO laminations & Copper Conductors like PCC,CTC or Bunched PCC.

- Step lap core with multiple sheets per bag is used in the core lamination jointing.

- Reduced stray loss & transformer noise by means of proper clamping using lean structures.

- Transformer windings are made with new state of the art conductors with high quality paper insulation manufactured under stringent quality norms.

- Transformer oil is directed to the winding to ensure efficient heat dissipation.

- Electrical stress analysis of coil assembly & insulation assembly design is done with advanced software.

- Transformers are designed & manufactured for overloading during service span as per relevant standards.

- Uniform and rigid clamping of the coil is ensured for withstanding forces during short circuits as well as in transportation & service.

- Efficient cooler design to operate under maximum stringent service conditions.

- Specially designed tanks using 3D software and manufactured with best quality steel & modern welding techniques are used to reduce oil volume and to withstand pressure during fault conditions.

- Tank stray losses are much reduced by CRGO & copper Shields.

- High Quality reliable Transformers are manufactured under stringent quality checks at all stages.

- Incoming material quality is ensured by stringent vendor approval procedures.

In all, we offer a reliable &smart transformer for your electrical grid.

Features:

- Design conforms to IS:1180 (Part 1) 2014, IS: 2026, BS 171, IEC 76 and other relevant standards.

- Latest manufacturing techniques to ensure cost effectiveness and reliability.

- Designed for 25 years of trouble – free performance.

- Very low power loss and low noise.

- Optimum utilization of active materials for sleek design.

- Withstands electrical impulses, thermal and dynamic stresses.

Optional Accessories:

- Magnetic Liquid Level Gauge (ANSI 71)

- Oil Temperature Gauge (ANSI 26)

- Pressure/Vacuum Gauge

- On-Load Tap Changer with RTCC Panel

- Current Transformers

- Contacts on Standard Gauges

- Pressure Relief Device (standard over 3 MVA)

- Winding Temperature Gauge (ANSI 49)

- Sudden Pressure Rise Relay (ANSI 63)

- Forced Air Cooling

- Lightning Arresters

- Load Break and Multi-Voltage Switches

- Stainless Steel Construction

- Digital Transformer Monitor

- Class 1 Div II/Marine/Corrosive Environments

- High Altitude

- Seismic Conditions and Anchoring

- For any frequently asked question

For any frequently asked questions